Modern Otomotiv Üretiminde CNC İşlemenin Rolü

The automotive industry has undergone significant transformations over the years, with technological advancements playing a pivotal role in shaping its evolution. Among these innovations, CNC (Computer Numerical Control) machining has emerged as a cornerstone of modern otomoti̇v üreti̇mi̇. This process, which utilizes computer-controlled machines to cut and shape materials with precision, has revolutionized the way vehicle components are produced. CNC machining’s ability to deliver high accuracy, efficiency, and consistency has made it indispensable in the production of complex automotive parts.

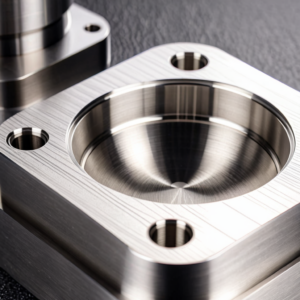

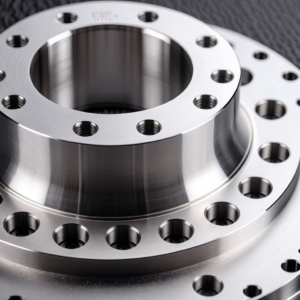

One of the primary reasons CNC machining is so integral to the automotive sector is its ability to produce components with exceptional precision. Modern vehicles comprise intricate parts, such as engine components and transmission systems, which require tight tolerances to function optimally. CNC machining excels in this regard, ensuring that each part meets stringent specifications, thereby enhancing overall vehicle performance and reliability. This level of precision not only improves the quality of the final product but also reduces the likelihood of mechanical failures, which is critical in the automotive industry where safety is paramount.

The automotive industry’s shift towards the use of advanced materials has further solidified CNC machining’s role. Contemporary vehicles increasingly incorporate lightweight materials like aluminum and carbon fiber to reduce weight and improve fuel efficiency. These materials, while beneficial, present challenges in machining due to their hardness and abrasiveness. CNC machines, however, are well-equipped to handle such materials, as they can be programmed to use specific cutting tools and speeds, ensuring effective machining without compromising material integrity.

Moreover, CNC machining has become a vital tool in the rapid prototyping and development phases of automotive manufacturing. The ability to quickly produce prototype parts allows manufacturers to test and refine designs efficiently, accelerating the overall development process. This capability is crucial in an industry where time-to-market is a key competitive factor. By enabling rapid iteration and refinement, CNC machining facilitates innovation and ensures that automotive companies can swiftly respond to market demands and technological advancements.

In addition to its role in prototyping, CNC machining supports just-in-time (JIT) manufacturing, a production strategy widely adopted in the automotive sector. JIT manufacturing emphasizes producing and delivering parts just in time to meet demand, minimizing inventory costs and production lead times. CNC işleme aligns perfectly with this approach, as it allows for the rapid production of high-quality parts in precise quantities, ensuring a smooth and efficient supply chain.

The integration of CNC machining with other advanced technologies, such as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), has further enhanced its effectiveness. This seamless integration enables a streamlined design-to-manufacturing process, reducing errors and improving overall efficiency. By leveraging these technologies, automotive manufacturers can optimize their production processes, ensuring that each component meets the highest standards of quality and performance.

Another significant advantage of CNC machining is its contribution to reducing material waste. The precision of CNC machines ensures that materials are cut and shaped with minimal waste, which is not only cost-effective but also environmentally beneficial. In an era where sustainability is a growing concern, this aspect of CNC machining aligns with the automotive industry’s efforts to adopt more eco-friendly manufacturing practices.

Looking ahead, the future of CNC machining in the automotive industry is poised for further innovation. Advances in artificial intelligence (AI) and machine learning are expected to enhance CNC systems, enabling predictive maintenance and optimized production processes. These advancements will likely lead

Current Trends In CNC Machining For The Automotive Industry

**CNC Machining for Automotive Industry: Current Trends**

In the automotive industry, CNC machining plays a pivotal role in manufacturing high-precision components essential for modern vehicles. As technology advances, CNC machining continues to evolve, adapting to the industry’s demands for efficiency, sustainability, and innovation. This article explores the current trends shaping CNC machining in the automotive sector.

One significant trend is the increased integration of automation and robotics. Automotive manufacturers are adopting robotic systems to handle tasks such as part loading and unloading, reducing human intervention and enhancing production efficiency. This automation not only accelerates workflows but also minimizes errors, ensuring consistent quality in components.

In addition to automation, the incorporation of artificial intelligence (AI) and machine learning is revolutionizing CNC machining. AI algorithms optimize machining processes by analyzing data to predict tool wear and reduce downtime. Machine learning further enhances this by improving part quality through iterative process refinement, making production more efficient and precise.

The automotive industry is also witnessing the rise of additive manufacturing (AM), commonly known as 3D printing. AM is being used alongside CNC machining to create complex geometries that traditional methods cannot achieve. Hybrid machines that combine AM and CNC machining are emerging, allowing for the creation and finishing of parts in a single process, which is particularly useful for producing lightweight components.

Speaking of lightweight materials, the industry’s shift towards materials like aluminum and carbon fiber is another key trend. These materials improve fuel efficiency and reduce emissions, aligning with global sustainability goals. CNC machining is adapting to handle these materials efficiently, ensuring precise and high-quality outcomes.

Sustainability is a growing focus, with manufacturers seeking eco-friendly practices. CNC machining is becoming more energy-efficient, and there is a push towards reducing waste and using recyclable materials. These efforts contribute to a greener manufacturing process, which is increasingly important for environmentally conscious consumers.

Moreover, the Internet of Things (IoT) is transforming CNC machining by enabling real-time monitoring and data exchange. This connectivity allows for predictive maintenance and optimized production planning, enhancing overall efficiency. Connected systems ensure that CNC machines operate at peak performance, reducing downtime and improving productivity.

Finally, customization and rapid prototyping are becoming essential in the automotive industry. CNC machining enables quick production of prototypes and customized parts, which is crucial for rapid product development and meeting diverse customer demands.

In conclusion, CNC machining is at the forefront of innovation in the automotive industry, driven by trends such as automation, AI, additive manufacturing, lightweight materials, sustainability, and IoT integration. As technology continues to

The Importance Of Material Selection In Automotive CNC Machining

**CNC Machining for Automotive Industry: The Importance of Material Selection in Automotive CNC Machining**

In the automotive industry, CNC machining plays a pivotal role in manufacturing components that require precision and durability. This process, controlled by programmed instructions, is essential for producing parts such as engine components and chassis elements. Central to this manufacturing process is the selection of materials, a factor that significantly influences both the production process and the final product’s performance.

Material selection is crucial because different materials possess unique properties, including strength, durability, weight, and thermal resistance. Each automotive part has specific requirements; for instance, engine components must withstand high temperatures and stresses, while body panels prioritize lightweight materials for fuel efficiency. The choice of material directly impacts the functionality and longevity of these components.

Mechanical properties are a primary consideration in material selection. Materials must meet specific strength, durability, and thermal requirements. For example, engine parts often use high-strength alloys like steel or titanium to endure extreme conditions, while components exposed to heat may utilize materials with high thermal resistance. These choices ensure reliability and performance under various operational stresses.

Weight considerations are another critical factor. Lightweight materials, such as aluminum and advanced composites, are increasingly used to enhance fuel efficiency and reduce emissions. This trend is particularly important in the development of electric vehicles, where minimizing weight can improve range and performance. However, lightweight materials must still meet necessary strength and durability standards.

Cost and availability also play a significant role. While high-performance materials like titanium offer excellent strength-to-weight ratios, their expense may limit their use. Manufacturers must balance material cost with performance needs, often opting for more affordable alternatives like aluminum alloys that provide a favorable balance of cost and capability.

Manufacturability is another key aspect. Some materials are easier to machine, affecting production time and cost. For instance, certain plastics and soft metals are more straightforward to process, reducing machining time and tool wear. Conversely, harder materials may require specialized tools and techniques, increasing production complexity and expense.

Environmental factors are increasingly influential in material selection. Regulations and consumer demand for eco-friendly options have led to a focus on sustainability and recyclability. Materials like aluminum and certain composites are favored for their recyclability, aligning with industry efforts to reduce environmental impact.

In conclusion, material selection is a foundational aspect of automotive CNC machining, impacting performance, efficiency, and sustainability. As advancements in materials science emerge, new possibilities like advanced composites and lightweight metals are reshaping the industry, particularly for electric vehicles. The careful consideration of mechanical properties, weight, cost, manufacturability, and environmental impact ensures that each component meets the necessary standards, driving innovation and excellence in automotive manufacturing.