Advantages Of Aluminum In CNC Machining Services

Aluminum has become a highly sought-after material in CNC machining services due to its unique combination of properties, making it an ideal choice for a wide range of industrial applications. From aerospace to automotive, consumer goods, and beyond, aluminum’s versatility, durability, and cost-effectiveness have solidified its position as a preferred material for precision machining. This article explores the advantages of aluminum in CNC machining services, highlighting why it remains a cornerstone of modern manufacturing.

One of the most significant advantages of aluminum is its lightweight yet high strength-to-weight ratio. Unlike heavier metals such as steel, aluminum offers exceptional durability without adding unnecessary bulk, making it particularly valuable in industries where weight reduction is critical. For instance, in the aerospace and automotive sectors, the use of aluminum components contributes to improved fuel efficiency and reduced energy consumption. This property also makes aluminum an excellent choice for portable devices and equipment, where ease of handling is essential.

In addition to its strength, aluminum is highly corrosion-resistant, especially when alloyed with other metals. This natural resistance to environmental factors such as moisture, salt, and chemicals ensures that aluminum parts maintain their integrity over time, even in harsh operating conditions. As a result, aluminum is often used in marine applications, outdoor equipment, and industrial machinery, where exposure to corrosive elements is a concern. Furthermore, aluminum’s corrosion resistance reduces the need for additional protective coatings, simplifying production processes and lowering costs.

Another significant advantage of aluminum is its excellent thermal and electrical conductivity. These properties make it an ideal material for heat sinks, electrical components, and other applications where efficient heat dissipation or energy transfer is required. For example, aluminum is widely used in the production of computer hardware, such as CPU heat sinks, due to its ability to effectively manage temperature fluctuations. Its high conductivity also makes it suitable for use in power transmission lines and other electrical systems.

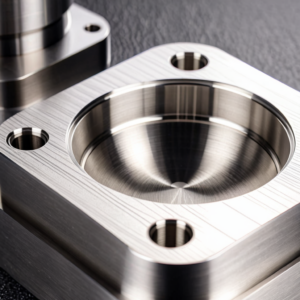

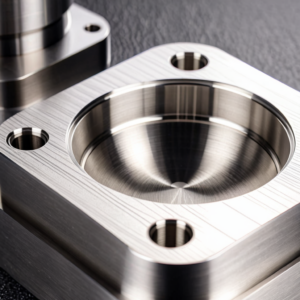

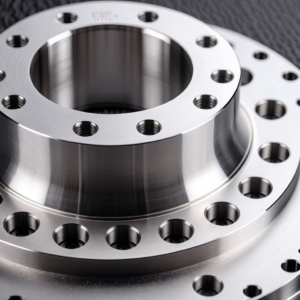

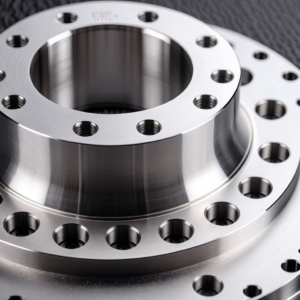

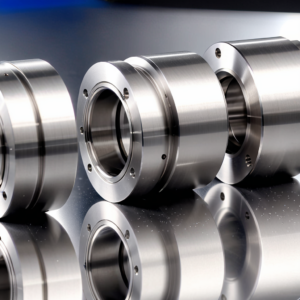

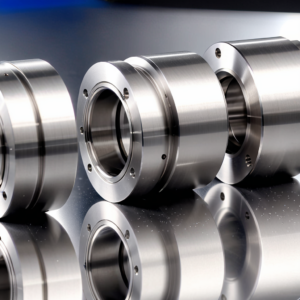

From a machining perspective, aluminum is highly favorable due to its soft, ductile nature, which allows for precise and efficient cutting. Compared to harder metals like steel or titanium, aluminum can be machined at faster speeds with less wear on tools, resulting in shorter production times and lower costs. Additionally, aluminum’s malleability enables the creation of complex geometries and intricate designs, making it a popular choice for custom CNC machining projects. This versatility is particularly beneficial for industries requiring tailored solutions, such as medical device manufacturing and precision engineering.

The cost-effectiveness of aluminum is another factor contributing to its widespread use in CNC machining services. While the initial cost of aluminum may be higher than some alternative materials, its durability, recyclability, and reduced need for post-machining treatments often lead to long-term savings. Aluminum’s high scrap value also makes it an environmentally friendly option, as it can be recycled repeatedly without losing its properties. This aligns with the growing emphasis on sustainability in manufacturing, making aluminum a responsible choice for businesses aiming to minimize their environmental impact.

In conclusion, the advantages of aluminum in CNC machining services are numerous and well-documented. Its lightweight nature, corrosion resistance, excellent conductivity, and ease of machining make it a versatile and cost-effective material for a wide range of applications. As industries continue to prioritize efficiency, sustainability, and precision, aluminum is poised to remain a cornerstone of modern manufacturing for years to come.

Applications Of Aluminum CNC Machining In Modern Manufacturing

Aluminum CNC machining has become a cornerstone of modern manufacturing, offering unparalleled precision and efficiency in producing high-quality components. This process, which utilizes computer-controlled machinery to shape aluminum, is integral to various industries due to its versatility and the material’s advantageous properties. Aluminum’s lightweight nature, corrosion resistance, and excellent thermal conductivity make it an ideal choice for diverse applications, from aerospace to consumer goods.

In the aerospace industry, aluminum CNC machining plays a pivotal role in crafting lightweight yet durable components essential for aircraft and spacecraft. The precision of CNC machining ensures that intricate parts, such as engine components and structural frames, meet stringent safety and performance standards. This not only enhances fuel efficiency but also contributes to the overall safety of air travel, making it a critical application in this field.

The automotive sector also benefits significantly from aluminum CNC machining. As manufacturers strive to reduce vehicle weight to improve fuel efficiency and lower emissions, aluminum parts become indispensable. From body panels to engine components, CNC machining allows for the creation of complex shapes that combine strength with minimal weight, thus supporting the industry’s shift towards more sustainable practices.

Consumer electronics is another domain where aluminum CNC machining shines, particularly in producing casings for devices like smartphones and laptops. The process not only ensures a sleek, durable exterior but also allows for the incorporation of intricate designs that enhance both functionality and aesthetics. This blend of form and function is crucial in a competitive market where design plays a significant role in consumer choice.

Furthermore, the healthcare industry leverages aluminum CNC machining for medical devices and equipment. The biocompatibility and durability of aluminum make it suitable for components used in surgical instruments and implants. The precision of CNC machining ensures that these parts meet the exacting standards required for medical applications, contributing to patient safety and treatment efficacy.

In the energy sector, aluminum CNC machining is employed in the production of components for solar panels and wind turbines. The lightweight and durable nature of aluminum is essential for creating efficient and long-lasting renewable energy systems. This application underscores the role of CNC machining in supporting sustainable energy solutions, aligning with global efforts to reduce environmental impact.

In conclusion, aluminum CNC machining is integral to advancing manufacturing across various industries. Its ability to produce precise, complex, and durable components makes it a vital tool in aerospace, automotive, electronics, healthcare, and energy sectors. As industries continue to evolve, the demand for efficient and sustainable manufacturing solutions will likely grow, ensuring the continued relevance of aluminum CNC machining. This process not only drives innovation but also supports sustainable practices, highlighting its importance in shaping the future of manufacturing.

The Process And Benefits Of Aluminum CNC Machining Services

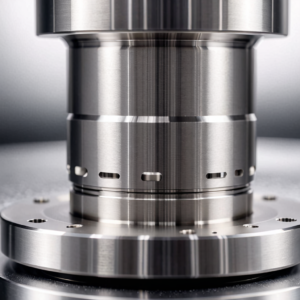

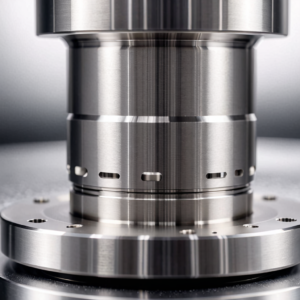

Aluminum CNC machining services have become a cornerstone in modern manufacturing, offering a blend of efficiency and precision that is hard to match. This process leverages computer numerical control (CNC) technology to craft intricate components from aluminum, a metal renowned for its lightweight, corrosion resistance, and excellent thermal conductivity. These attributes make aluminum a preferred choice across various industries, from aerospace to consumer electronics.

The process begins with design, where engineers utilize CAD software to create detailed models of the desired components. This stage is crucial as it sets the foundation for the entire production process. Once the design is finalized, it is translated into G-code, which guides the CNC machines. The machining phase involves cutting, drilling, and shaping the aluminum workpiece with high precision. Post-machining, a finishing process is applied to enhance the component’s surface quality, whether through anodizing, polishing, or applying a protective coating. Quality control is the final step, ensuring each piece meets specified standards.

The benefits of aluminum CNC machining are manifold. Precision is paramount, as CNC machines operate with minimal error margins, reducing the need for manual adjustments. This accuracy is complemented by speed, allowing for rapid production even of complex designs. Cost-effectiveness is another advantage, as automation reduces labor costs and minimizes material waste. Versatility shines through in the range of applications, from prototypes to large-scale production. Additionally, the use of aluminum promotes sustainability, being fully recyclable and energy-efficient in production.

In conclusion, selecting the right CNC machining service is vital to harnessing these benefits effectively. A reputable provider ensures high-quality outcomes, meeting both project requirements and deadlines. As industries evolve, aluminum CNC machining stands as a testament to innovation and efficiency, driving progress across the manufacturing spectrum.