The Advantages Of Aluminum In CNC Machining

Aluminum has become a preferred material in CNC machining due to its unique combination of properties that make it ideal for a wide range of applications. Its growing popularity stems from its lightweight nature, corrosion resistance, and excellent thermal conductivity, among other benefits. As industries seek materials that offer both performance and cost-effectiveness, aluminum stands out as a versatile and reliable choice.

One of the primary advantages of aluminum in CNC machining is its lightweight yet strong structure. With a high strength-to-weight ratio, aluminum is particularly favored in industries such as aerospace and automotive, where reducing weight is crucial for improving fuel efficiency and performance. This property allows manufacturers to create durable parts without compromising on weight, making it an ideal material for components that require both strength and portability.

In addition to its physical properties, aluminum’s natural resistance to corrosion is another significant advantage. When exposed to air, aluminum forms a thin oxide layer that protects it from environmental factors like moisture and chemicals. This inherent corrosion resistance makes it suitable for applications in harsh environments, such as marine hardware and outdoor equipment, reducing the need for additional protective coatings and extending the lifespan of the parts.

Furthermore, aluminum’s excellent thermal and electrical conductivity makes it a preferred choice for applications requiring efficient heat dissipation or electrical conduction. This property is particularly valuable in the electronics industry, where heat sinks and connectors are commonly made from aluminum to ensure optimal performance and prevent overheating. Its conductivity also makes it suitable for use in various electrical components, enhancing overall system efficiency.

Cost-effectiveness is another factor that contributes to aluminum’s popularity in CNC machining. Compared to other metals, aluminum is generally less expensive, which helps reduce production costs. Additionally, aluminum’s ease of machining allows for faster production times, further lowering overall expenses. This cost-efficiency is particularly beneficial for businesses looking to maintain quality while managing budgets.

Moreover, aluminum’s recyclability is a significant environmental advantage. It can be recycled repeatedly without losing its properties, making it a sustainable choice for manufacturers. Recycling aluminum consumes less energy than producing it from raw materials, which not only reduces environmental impact but also offers cost savings for companies. This eco-friendly aspect aligns with the growing demand for sustainable practices in manufacturing.

In terms of aesthetics, aluminum can be anodized to enhance its appearance and durability. Anodizing creates a protective layer that can be colored, offering a wide range of finishes. This makes aluminum parts not only functional but also visually appealing, suitable for applications where design is important, such as consumer electronics and architectural features.

In conclusion, aluminum’s combination of lightweight strength, corrosion resistance, thermal conductivity, cost-effectiveness, recyclability, and aesthetic options makes it a top choice for CNC machining. Its versatility across various industries ensures that it remains a preferred material for manufacturers seeking both performance and sustainability. As industries continue to evolve, aluminum’s advantages position it as a key material in meeting the demands of modern manufacturing.

Applications Of Aluminum Parts In Various Industries

Aluminum parts CNC machining is a pivotal process in modern manufacturing, leveraging the unique properties of aluminum to produce components with high precision and efficiency. Aluminum’s lightweight, corrosion resistance, and excellent thermal conductivity make it a preferred material across various industries. This article explores the diverse applications of aluminum parts, highlighting the integral role of CNC machining in shaping these components for specific industrial needs.

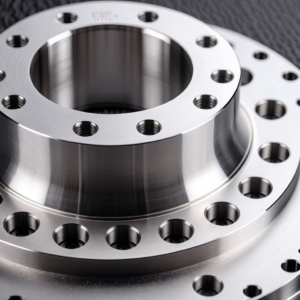

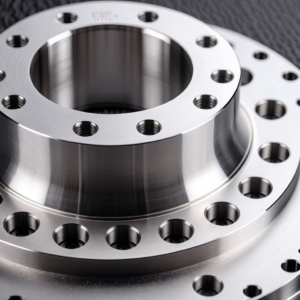

In the aerospace industry, aluminum’s combination of strength and lightness is crucial for aircraft and spacecraft components. CNC machining allows for the precise fabrication of intricate parts such as aircraft skins and engine components, contributing to fuel efficiency and structural integrity. The ability to create complex geometries with tight tolerances ensures that these parts meet the stringent safety and performance standards of the aerospace sector.

The automotive industry also benefits significantly from aluminum parts. By reducing vehicle weight, aluminum contributes to improved fuel efficiency and lower emissions. CNC machining is employed to produce engine blocks, cylinder heads, and body panels, where precision and durability are paramount. This process ensures that automotive components are both functional and aesthetically pleasing, aligning with the industry’s demand for high-quality finishes.

In the electronics industry, aluminum’s thermal conductivity is a key asset. Heat sinks and casings for electronic devices are often machined from aluminum to effectively dissipate heat, protecting sensitive components from thermal damage. CNC machining enables the creation of intricate cooling systems, ensuring optimal performance and longevity of electronic devices.

The construction industry utilizes aluminum for structural components due to its durability and resistance to corrosion. Facades, frameworks, and other architectural elements are fabricated using CNC machining, offering both strength and aesthetic appeal. This process allows for custom designs that meet specific architectural requirements while maintaining structural integrity.

Furthermore, the medical industry benefits from aluminum’s non-toxic properties. Equipment such as MRI machines and surgical instruments are manufactured using CNC machining, ensuring precision and sterility. The ability to produce complex shapes with high accuracy is essential for medical applications where reliability is critical.

In conclusion, aluminum’s versatility, combined with the precision of CNC machining, makes it an indispensable material across various industries. From aerospace to healthcare, the applications of aluminum parts underscore its importance in modern manufacturing. CNC machining not only enhances the performance of these components but also drives innovation, enabling industries to meet the demands of a rapidly evolving world.

A Step-By-Step Guide To CNC Machining Aluminum Parts

**Aluminum Parts CNC Machining: A Step-By-Step Guide**

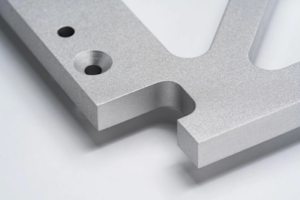

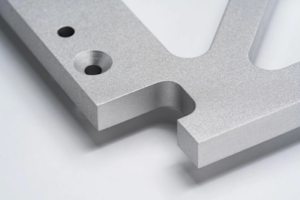

CNC machining is a widely used manufacturing process that offers precision and efficiency, making it ideal for producing aluminum parts. Aluminum’s lightweight, corrosion resistance, and durability make it a preferred material in various industries, including aerospace, automotive, and electronics. This guide outlines the steps involved in CNC machining aluminum parts, ensuring a comprehensive understanding of the process.

The journey begins with the design phase, where computer-aided design (CAD) software is utilized to create a digital model of the part. This stage is crucial as it determines the feasibility and manufacturability of the design. Engineers must consider factors such as tolerances, material properties, and the intended application to ensure the design is optimal for CNC machining. Design for manufacturability is key to avoiding costly revisions later in the process.

Once the design is finalized, the next step is tooling preparation. This involves selecting the appropriate cutting tools, such as carbide or diamond-coated tools, which are ideal for machining aluminum due to their hardness and wear resistance. The setup of the CNC machine is also critical, ensuring that all parameters, including spindle speed and feed rates, are correctly configured. Coolant systems are often employed to prevent overheating and extend tool life.

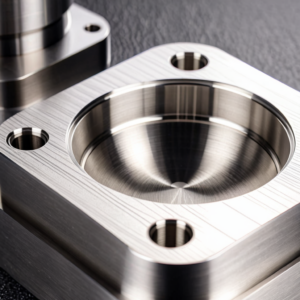

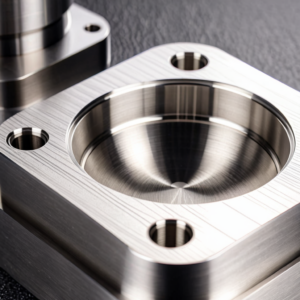

With the machine prepared, the machining process commences. The CNC machine executes the programmed instructions, typically in G-code, to perform operations like milling, turning, and drilling. Aluminum’s high machinability allows for high-speed machining, producing complex geometries with precision. The material’s softness, however, necessitates careful handling to avoid defects.

Following machining, post-processing steps are essential to enhance the part’s surface finish and durability. Techniques such as sanding, polishing, or applying coatings like anodizing are commonly used. These treatments not only improve aesthetics but also provide corrosion resistance and durability.

Quality control is the final step, ensuring the part meets specifications. Inspections involve checking dimensions, surface finish, and any additional treatments. Advanced metrology tools may be used for precise measurements, guaranteeing the part’s quality and performance.

Throughout the process, safety and efficiency are paramount. CNC machining offers advantages over traditional methods, including reduced material waste and faster production times. By adhering to these steps, manufacturers can produce high-quality aluminum parts efficiently, meeting the demands of various industries. This guide underscores the importance of each stage, from design to delivery, in achieving successful CNC machining outcomes.