Руководство по обработке нержавеющей стали на станках с ЧПУ (2026 Deep Dive Edition)

Engineering Methodology for Material Behavior, Process Risk, and Reliable Delivery

Foreword: The Underestimated Complexity of Stainless Steel Machining

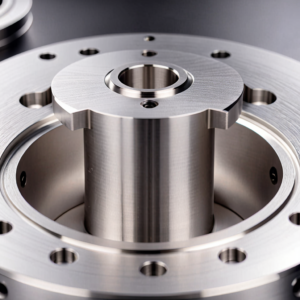

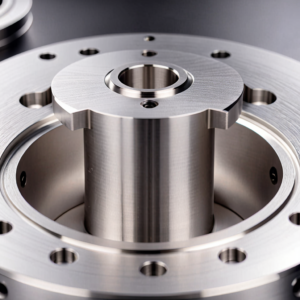

Stainless steel remains one of the most widely used—and yet most frequently underestimated—material systems in CNC machining. From mission-critical structural components and shafts to high-reliability parts for medical, energy, automotive, and consumer electronics, stainless steel is ubiquitous.

However, significant cost overruns, delivery delays, and quality fluctuations in manufacturing are often directly linked to an insufficient understanding of stainless steel’s unique material mechanics.

This 2026 Deep Dive Guide will systematically unpack the core issues, providing an engineering-driven approach:

What are the root causes of stainless steel’s machining difficulty?

Сайт true processing differences between common grades (e.g., 304 vs. 316 vs. 17-4PH).

Identifying and engineering control strategies for high-risk geometric features.

Сайт best practices for stable, predictable delivery in high-stakes stainless steel projects.

1. The Core Engineering Challenges of Stainless Steel CNC Machining

Stainless steel is a thermodynamically and mechanically complex material that requires a specialized approach, moving beyond generic “feed and speed” tables.

1.1 Work Hardening: The Primary Adversary in Machining

Most austenitic stainless steels (such as 304 and 316) exhibit significant work hardening during the cutting process. This is the single most critical factor driving up costs and reducing quality.

Mechanism: As the cutting edge displaces and strains the material in the shear zone, its localized hardness rapidly increases. The next cutting pass is therefore operating on a much harder, already strained layer of material.

Consequence Chain: If cutting parameters are incorrect (e.g., shallow depth of cut or low feed rate), the hardened layer will accumulate with each pass, leading to a vicious cycle.

Tool Life: Rapid and catastrophic tool wear, chipping, and premature failure.

Surface Integrity: Unstable surface finish and poor metallurgical integrity.

Dimensional Accuracy: Increased dimensional drift and burr formation.

Engineering Conclusion: Stainless steel machining is not a race against speed, but a fight for correct engagement. Incorrect parameters are exponentially more damaging than slow cycle times.

1.2 Low Thermal Conductivity: The Heat Concentration Problem

Compared to highly conductive materials like aluminum, stainless steel has significantly poor thermal conductivity.

Mechanism: Cutting heat, which can reach hundreds of degrees Celsius, cannot dissipate quickly into the bulk material. This heat concentrates at the tool-chip interface and the cutting zone.

Consequence Chain: High tool-tip temperatures lead to thermal softening, rapid chemical wear, built-up edge (BUE) formation, and eventual catastrophic failure (chipping or crater wear).

Engineering Implication: The influence of cooling strategy (coolant pressure, flow rate, jet targeting, and concentration) is exponentially more critical for stainless steel than for aluminum or mild steel. Advanced techniques like High-Pressure Through-Spindle Coolant (HPTC) are often mandatory.

1.3 High Strength and High Toughness: Source of Vibration and Instability

Stainless steels typically combine a relatively high yield strength with excellent ductility (especially 304/316).

Mechanism: This combination results in high cutting forces and a tendency for the material to resist shearing and instead deform elastically before separation.

Consequence Chain:

Chatter Risk: Increased overall cutting forces amplify the risk of system vibration (chatter), particularly in long-reach or slender tools.

Deflection: Thin-walled or high-aspect ratio features are prone to deflection, leading to dimensional instability and “pushing” of the workpiece away from the tool.

2. Differentiated CNC Machining Characteristics by Stainless Steel Grade

A one-size-fits-all strategy for stainless steel will fail. Selecting the correct processing strategy requires a deep understanding of the alloying elements and their impact on machinability.

2.1 304 / 304L (The Workhorse: Frequently Misapplied)

Characteristics: Highly prone to work hardening; high toughness and ductility; difficult to maintain a consistent surface aesthetic.

Typical Risks: Rapid, unpredictable tool wear; high incidence of tool breakage in small/deep features; significant dimensional spring-back in thin sections.

Engineering Strategy: Utilize sharp, positive-rake geometry tooling to minimize initial material deformation; employ high feed rates coupled with a sufficient depth of cut (DOC) to ensure the tool always enters below the previous pass’s hardened layer (“getting under the skin”); minimize repeated cutting over the same area.

2.2 316 / 316L (The Corrosion King: Increased Difficulty)

Characteristics: Contains Molybdenum (Mo) for superior corrosion resistance, but this further exacerbates work hardening and increases cutting resistance compared to 304.

Typical Risks: Extremely short tool life; high probability of BUE formation; greater heat generation.

Engineering Reality: 316’s processing cost is inherently and predictably higher than 304. If designs mandate 316 without considering machinability (e.g., sharp corners, deep pockets), the cost delta can become exponential.

2.3 303 (The Machinability Champion)

Characteristics: Optimized for machining through the addition of Sulfur (S) or Selenium (Se), which forms small, brittle sulfide inclusions. These inclusions act as chip breakers, dramatically improving cutting action.

Преимущества: Significantly extended tool life; stable surface quality; high processing speeds.

Trade-Offs: Reduced corrosion resistance and poor weldability compared to 304/316.

Engineering Conclusion: When the application environment permits, 303 offers the highest machinability-to-cost ratio and is the preferred choice for high-volume shafts, fittings, and connectors.

2.4 17-4PH (Precipitation Hardening Stainless Steel)

Core Advantage: High strength and adjustable mechanical properties via precise thermal treatment. Good stability compared to austenitic grades.

Key Variable: Heat Treatment State:

Solution Treated: Soft and relatively easy to machine.

Hardened States (H900, H1025, etc.): High hardness and abrasive wear, significantly increasing machining difficulty.

Engineering Strategy: Perform the vast majority of roughing and semi-finishing in the Solution Treated state, reserving only minimal, high-precision finishing passes for the post-heat-treat state to correct for dimensional movement.

3. High-Risk Features and Engineering Control Methodologies

Structural geometry interacts severely with stainless steel’s inherent material challenges. Failure to address these risks results in scrap and delays.

3.1 Thin-Walled Features (The Ultimate Stability Test)

Sources of Risk: High cutting forces induce clamping deformation; internal stress relief causes post-machining spring-back; concentrated heat leads to localized warpage.

Control Strategies:

Incremental Stock Removal: Employ multi-stage roughing and finishing with decreasing depths of cut to manage force spikes.

Symmetrical Machining: Balance residual stress by removing material symmetrically where possible.

Fixturing: Use specialized soft jaws, custom contour clamps, or vacuum fixturing to distribute clamping force and minimize distortion.

Stress Relief Cycles: Incorporate dedicated stress-relief heat treatments between heavy roughing and finishing passes for critical parts.

3.2 Deep Holes and Small Holes (High Tool Breakage Zone)

Risk Points: Chip evacuation difficulty (chips packing in the flute); inadequate coolant penetration; compounding work-hardened layers deep inside the hole.

Control Strategies:

Dedicated Tooling: Utilize specialized high-helix drills or gun drills designed for effective chip transport.

High-Frequency Pecking: Employ a high-frequency, short-stroke pecking cycle to continuously break the chip and clear the cutting zone.

High-Pressure Internal Coolant: Mandatory use of HPTC to flush chips and provide direct cooling to the tool tip.

3.3 High-Tolerance Mating Surfaces (Thermal and Stress Instability)

Dimensional stability during the finishing phase of stainless steel is often inferior to that of aluminum or even hardened tool steel.

Common Issues: Dimensions are acceptable when measured hot immediately after machining but drift out of tolerance upon cooling; subsurface stress leads to premature wear.

Engineering Strategy:

Thermal Equilibrium: Ensure the workpiece has reached thermal equilibrium (ideally near the inspection temperature) before the final precision pass.

Process Sequence: Critical mating features must be machined last in the sequence to minimize subsequent stress or distortion.

CMM Datum Alignment: Use a unified Coordinate Measuring Machine (CMM) datum reference system for inspection that precisely mimics the functional datums on the drawing, ensuring alignment traceability.

4. The Iron Triangle: Tooling, Parameters, and Cooling

The success of stainless steel machining hinges on the harmonious selection of the cutting parameters, tool material, and cooling method.

4.1 Tooling Selection Principles (The Battle for Sharpness)

Geometry: Prioritize high positive rake angles and sharp cutting edges to reduce cutting pressure and minimize work hardening.

Substrate & Coating: Utilize tough carbide substrates (e.g., PVD coated grades) with specialized coatings that possess high lubricity and resistance to BUE.

Tool Management: Tool condition monitoring is paramount. A tool’s status (sharp vs. slightly fatigued) is a far greater variable than the brand name. Avoid using tools near the end of their predicted life for finishing passes.

4.2 Cutting Parameter Logic (Aggressive Engagement)

Feed Rate over Speed: Prioritize a high feed rate ($f_z$) to maintain aggressive cutting engagement and ensure the tool is constantly slicing under the work-hardened layer created by the previous rotation.

The “Rubbing” Danger: Avoid low cutting speeds combined with low feeds, which lead to “rubbing”—this is the fastest path to heat generation, work hardening, and catastrophic tool failure.

Stable Cutting Zone: Parameters must be designed to maintain the tool within its “stable cutting regime,” balancing chip load, heat generation, and tool life predictability.

4.3 Cooling Strategy (Heat and Chip Evacuation)

Function: Coolant’s primary job is not just cooling the workpiece, but cooling the tool tip and flushing chips away from the cutting zone before they can be re-cut or re-circulated.

Targeting: The coolant jet must be precisely aimed to penetrate the chip-tool interface. Advanced systems use adjustable, high-velocity nozzles.

HPTC: High-pressure coolant ($\geq 70 \text{ bar}$) is particularly effective in stainless steel as it creates a hydrodynamic wedge that lifts the chip, reducing friction and rapidly removing heat.

5. Surface Quality and Post-Processing Realities

Surface finish extends beyond a simple Ra value; it involves subsurface integrity and stress.

5.1 True Origin of Surface Roughness

Primary Causes: The dynamic state of the cutting edge (wear), cutting process vibration (chatter marks), and instability within the work-hardened layer.

Critical Note: $\text{R}_a$ compliance does not equal controlled surface quality. Subsurface micro-cracks or excessive residual tensile stress are not captured by standard $\text{R}_a$ readings but are critical for parts subject to fatigue or sealing requirements.

5.2 Common Post-Processing Risks

Polishing: Can mask subsurface defects but risks compromising dimensional tolerances and changing the surface energy.

Passivation: Essential for maximizing corrosion resistance but must be controlled to prevent etching or affecting fitment and thread tolerances.

Abrasive Blasting: Often used for aesthetic purposes but risks introducing compressive surface stress and significantly dulling critical edges or internal features.

Engineering Requirement: The customer must clearly specify which surfaces are functional (must retain machined state) and which are aesthetic (allow post-treatment).

6. Quality and Inspection: Key Control Points for Stainless Steel

6.1 Inspection Goes Beyond Dimensional Checks

In stainless steel projects, the focus must expand to include:

Geometric Tolerances: Rigorous checks of flatness, perpendicularity, and co-axiality (which are highly sensitive to stress release).

Surface Integrity: Visual and potentially non-destructive testing (NDT) for tears, burns, micro-cracks, or evidence of thermal damage.

Material Certification: Traceability of the material certificate (MTR) and verification of dimensional consistency before and after any required heat treatment.

6.2 The Value of FAI and Process Lock-Down

Reliable stainless steel delivery is always system-dependent, never accidental. It requires:

Strict First Article Inspection (FAI): FAI must include not only CMM checks but a sign-off on the tooling, fixturing, and the locked-down NC program.

Process Control: Rigorous logging of key variables: tool life/change cycles, coolant concentration, spindle load trends, and documented post-machining stress relief.

7. Cost and Lead Time: The Stainless Steel Volatility Factor

The volatility in stainless steel projects is a function of the material’s hostility, not just the cycle time.

7.1 True Drivers of Cost Escalation

Tooling Consumption: The largest variable cost. Unpredictable tool failure can immediately void a quote.

Rework Rate: High scrap and rework due to dimensional instability or surface defects.

Reduced Machining Rhythm: Mandatory slowing of the process (deep pecking cycles, long coolant cycles) to manage risk.

Documentation & Inspection: Increased need for process evidence and critical dimensional checks.

7.2 Common Causes of Lead Time Instability

Surface Defects $\rightarrow$ Rework: A simple scratch on an aesthetic surface can force a full process restart.

Heat Treat Dimensional Shift: Failure to correctly predict and compensate for thermal movement.

Process Switching: Each change in part version or small-batch setup requires lengthy re-validation of the cutting parameters to avoid the work-hardening risk.

Conclusion: The Mature Standard for Stainless Steel CNC Machining (2026)

A genuinely mature stainless steel CNC machining solution, fit for 2026 demands, must achieve the following:

Material-Behavior Driven: The solution must be based on understanding the material’s thermodynamics and mechanics, not just anecdotal experience.

Process Engineering: Use fixture and process design to actively counteract work hardening and thermal instability.

Risk Management: Control risks at the design/planning stage, reducing reliance on costly rework.

Data and System Assurance: Utilize systems (MES, HPTC monitoring, automated CMM) to ensure the repeatability and predictability of the delivery.

The essence of stainless steel CNC machining is not “getting the material cut,” but “getting the material cut consistently and predictably.”